Kawanaka Group

The Japanese automobile industry continues to change drastically and demonstrate its presence even in an era of global competition. Roughly 30,000 parts are necessary to make one car, and at the heart of these parts is high precision technology. That is to say, cars are the fruit of the Japanese manufacturing spirit and technology.

This is the company profile of the Kawanaka Group, which plays this crucial role in its work alongside the Japanese automobile industry.

Kawanaka Precision Industry Co., Ltd.

We have set up factories in Kadoma, Osaka and Koga, Shiga, complete with equipment, working environment, and technology that can meet the needs of the automobile industry, from dye molding of small parts to 3,000 ton class transfer molds.

In addition to having the latest equipment, the Shiga factory takes advantage of its location to create even more convenient delivery to our clients in the automobile industry gathered in the Chubu area.

Head Office Factory

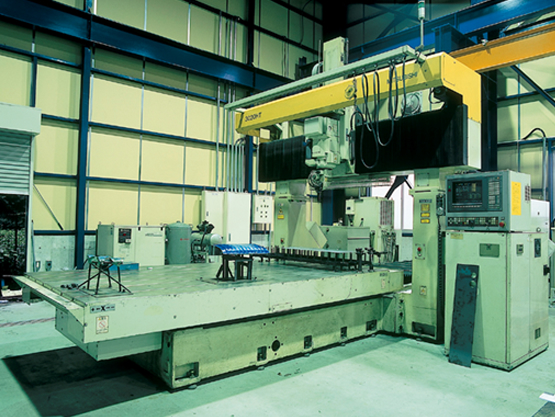

The Head Office Factory, located in Kadoma-City, Osaka-Prefecture, is the general information center of the Kawanaka Group. Leveraging its size and facilities, the factory can manufacture a wide range of metal dies, from dies of small components to large dies of the 3000 ton class.

Kadoma Second Factory

Kadoma Second Factory is the manufacturing center of Kawanaka Group, located in the same area as the Head Office in Kadoma-City, Osaka-Prefecture, It is equipped with 4 machining centers for machining large components and is responsible for the final finishing touches of DNC machining of metal dies.

Daito Factory

Located in Daito-City, Osaka-Prefecture, the factory is responsible for machining large components, the strength of the Kawanaka Group. It is mainly in charge of operations including 2.5D machining and 3D shape machining. 2.5D machining process of metal cast, 1D machining process of steel material, assembly machining for unifying 1.5D machining processes (the process before DNC process) are available

Shiga Factory

Shiga Factory, located along the National Road Route 1 in Koka-City, Shiga-Prefecture, is a manufacturing center that focuses on the ease of access into the Kansai, Tokai and Kanto regions. It is capable of manufacturing and finishing dies and transfer dies ranging from 300 tons to 3000 tons.

| Location |

|

|---|---|

| Our Business |

Head Office Factory

Kadoma Second Factory

Daito Factory

Shiga Factory

|

Kawanaka Ironsmith Co., Ltd.

Kawanaka Ironsmith Co., Ltd, with its Head Office Factory located in Shijonawate-City Osaka-Prefecture, the founding place of the Kawanaka Group. This is where “Kawanaka DNA” was born and is inherited until the present day. It is in charge of manufacturing metal dies under 300 tons, of all types in the lineup. The factory receives a high evaluation for its stable high quality and delivery time. For the automotive industry, it specializes in progressive dies.

| Location | 3-6-40, Nakano, Shijonawate-City, Osaka-Prefecture, 575-0052, Japan TEL.072-878-1199 FAX.072-878-2527 Access Map |

|---|---|

| Our Business |

|

KawaG Technology Co., Ltd.

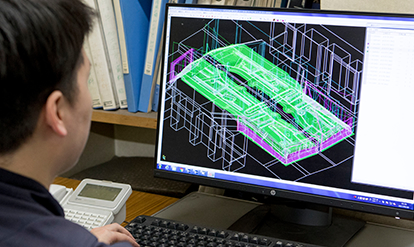

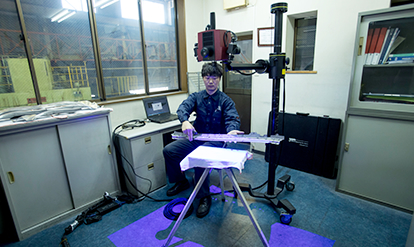

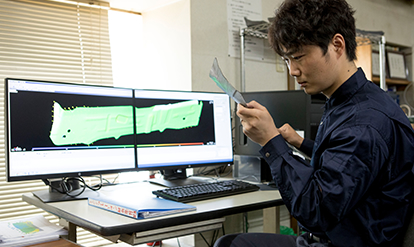

The Kawanaka Group is a leader in the industry of designing and manufacturing metal dies for automobiles components. It includes 3 associated companies, Kawanaka Precision Industry Co., Ltd, Kawanaka Ironsmith Co., Ltd, and KawaG Technology Co., Ltd. The Kawanaka Group’s strength is in making metal dies with high precision and high quality. This strength is supported by extensive expertise and high technology cultivated from more than 40 years of experiences in the industry. In recent years, we succeeded in minimizing operations by making full use of 3D CAD/CAM software “Space-E”, 3D Scanner “ATOS”, press forming simulation system “JSTAMP” for ultra-high-tensile steel die-making.

Design

Design

Modeling & Processing Data

Modeling & Processing Data

Inspection

Inspection

Modeling & Processing Data

Modeling & Processing Data

| Location |

3-6-40, Nakano, Shijonawate-City, Osaka-Prefecture, 575-0052, Japan TEL.072-813-7918 FAX.072-813-7917 Access Map |

|---|---|

| Our Business |

|