Guide to Metal Die Products

Here, we introduce our maimold products, the progressive dye and transfer mold made from high tensile strength materials (100 kg class) that are specialized to mold difficult shapes.

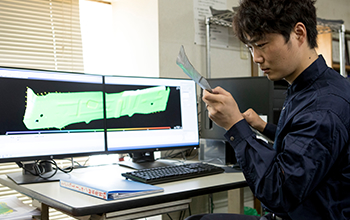

Manufacturing Process

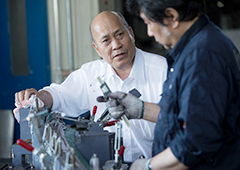

Here, we introduce a series of dye mold manufacturing processes, from modeling to molding simulation, creation of processing data, as well as inspection, fine-tuning, and shape reconstruction.

Quality Control

In order to respond to increasing delivery speed, quality, and price needs, we’ve established a strict quality control system in our quest to improve production capacity and molding technology.

Group Companies

Here, we introduce the companies and factories that belong to Kawanaka Group.

Kawanaka Precision Industry Co., Ltd.

The factory that manufactures press dyes of up to 3000 for transfer and 1500 for PRG (progressive). At factories located in Kadoma, Osaka, and Koga, Shiga, we carry out technical research and manufacturing of high tensile molding.

Shiga Factory

This manufacturing base does everything from fine-tuning to finalization and shipping of dye molds built at the head office.

Kawanaka Ironsmith Co., Ltd.

The factory, located in Shijonawate, Osaka, manufactures press dyes up to 300 tons. The factory manufactures high tensile for small and medium dyes (under 300 tons), difficult transfers and PRG (progressive) dyes.

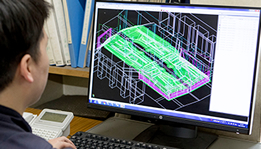

KawaG Technology Co., Ltd.

All of the Kawanaka Group’s dye designs, systems, and quality control (fine-tuning) is managed by digital tools, which serve as the brains of the Kawanaka Group. Training of engineers and supervisors (temp staff work)

Recruitment Information

This is a message for those seeking what the Kawanaka Group aims for.

The kind of person we are looking for

The kind of person we are looking for Comments from senior staff

Comments from senior staff Recruitment guidelines

Recruitment guidelines